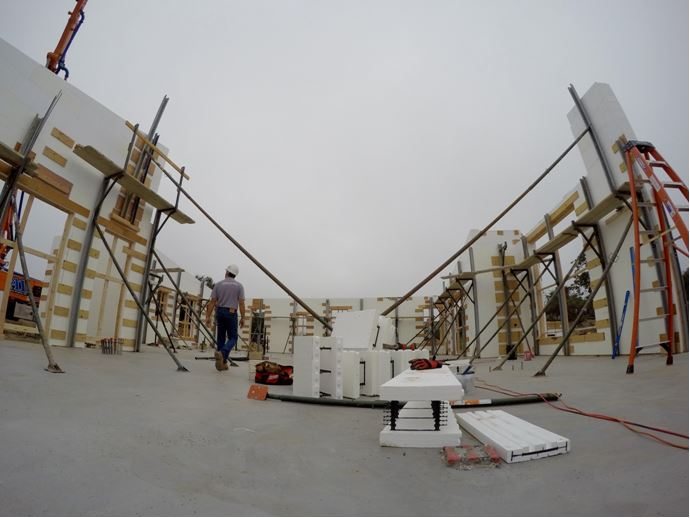

Hambro Floor Install in ICF home

5 Reasons Why to Build an ICF Home

1) Build for the Future: Innovation with ancillary benefits

Built out of the most advanced technology available in structural concrete development. Insulated Concrete Forms (ICF’s) are constructed from recycled polypropylene plastics and EPS foam comprised of poly styrene granulated beads. They make versatile, lightweight building blocks composed of over 98% air and water and about 2% recyclable plastics.

When building with the form, rebar is first placed in the plastic webs between the styrofoam. Concrete is then poured into the center of the block creating a pre-insulated, structurally sound and durable wall. This innovative way of building provides a development that will stand strong through the test of time.

2) Low Maintenance: Free of dry rot, mildew and pests. No leaky walls & contractor friendly installation.

ICF structures leave no room for any unwanted invaders in your home. Built of non-organic materials (concrete and foam), ICF walls will never have mold, mildew or dry rot. This also means you don’t have to worry about rodents or insects making a home where you live. By also generating airtight walls, ICF’s shut out drafts that may cause dust or allergies. This provides a cleaner and much healthier way of living. Build right the first time and don’t waste money on repairs down the road.

3) Energy Savings: Save up to 40-50% on heating and cooling costs while still maintaining the most tranquil environment.

Designed with a factory R-value of 24 in the EPS panels, ICF’s are capable of reaching 40+ R-values following concrete embedment. That means no extra time and costs spent on adding insulation throughout construction.

The Insulated Concrete Form creates a thermal barrier that naturally regulates the inside temperature of the house or structure. Therefore staying cool even in agonizing heat, and comfortably warm in the harsh winter cold. This means saving tremendous amounts in circulated air costs. You can reduce your energy bills by 40% or greater just by simply building your development’s walls out of ICF’s. Since these savings are built in, they start right away and last forever.

4) Customize: Versatile design capabilities, architecturally diverse, thick walls, straight walls, convenient form options. Whatever your design, be assured you have the same durability and insulation. Don’t sacrifice style for sustainability!

Whether an architect is designing a commercial building, or a homeowner is building their dream home, no one should have to sacrifice style for durability and sustainability. With ICF’s you won’t have to. We offer forms in a wide range of sizes, widths and angled corners.

ICF forms accommodate all types of rounded sections so when building unique radius walls there’s always a form that will fit. Whatever you can dream up, there’s a great way to build it strong and quickly out of ICF’s. Having a well trained and certified installation company always helps achieve the best and most cost effective way to construct all the unique aspects of your home’s design.

5) Build Value into Your Home: higher resale value, better quality of living, cleaner living. Resistant to weather and elements.

We aren’t just talking about R-Value. When you choose ICF’s for your project you start building value into your home or development from the very first block to the final construction. An ICF development will have a more personalized design and feel. It will provide a higher quality of living, a cleaner environment for your family and low maintenance costs in addition to providing the safest structural conditions.

Delivering a 4 hour fire rating, complying with the highest ICC codes in earthquake seismic zones, deterring high wind tornadoes and all the elements of nature, ICF buildings are incredibly resilient and reliable. This gives you both peace of mind and brings down expenses as well. All while providing a way of building that is leaving an extremely low carbon footprint. ICF’s are almost entirely composed of reusable natural resources making up only 1% in landfills in comparison to 25% being paper and cardboard. ICF’s are also the fastest way to achieve LEED accredited points to any project big or small.

Forming Solutions has been an ICF distributor and technical advisor for over 18 years. We also carry 30 plus years of experience as masonry contractors and have developed many projects ourselves. We pride ourselves on being there for the construction of nearly every type of building or project. From a small residence to a large commercial structure, we firmly believe ICFs are the best way to build. In our experience, we have seen and used many different ICF forms and we stand behind our flagship product: Fox Blocks. This industrial strength ICF form system is manufactured by Airlite Plastics, who have been on the cusp of the best technological advancements of the ICF industry and make their forms in a smart sustainable way by recycling their own plastics and repurposing them into a building block that will never have to be replaced.

Be a part of the future of green building. Build your next project that will endure while saving you money. Are you building out of ICF’s?